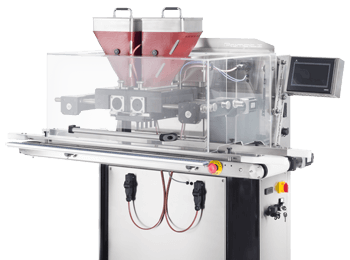

Chocolate line

Pomati Group designs and builds customized production lines. Our products are the result of our constant attention to the newest materials and most innovative technologies to be leveraged for chocolate processing small chocolates production, in small- and medium-size factories. Our close interaction with our clients allows us to meet highly diversified demands for customized products.