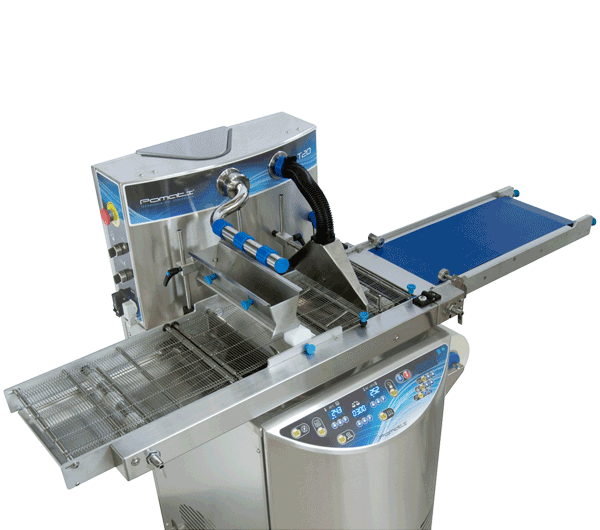

Enrobing belt

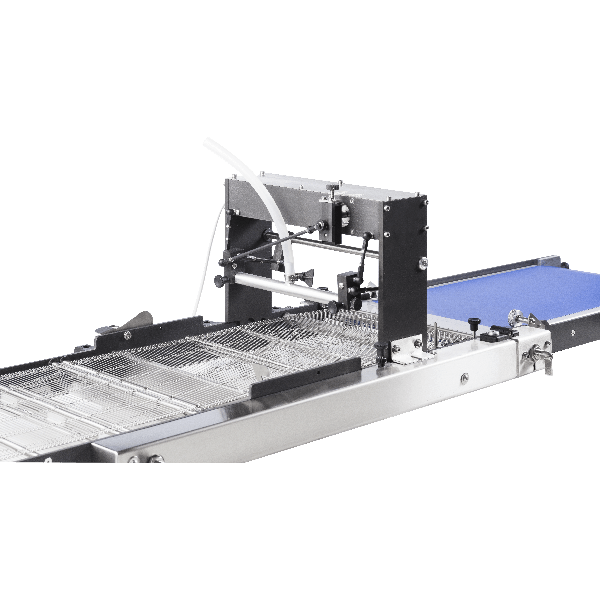

- Network loading with start/stop function

- Re-enrobing network with product vibration area

- Unloading conveyor belt featuring a start/stop system fed by a paper roll

- Rapid release of unloading conveyor belt for re-enrobing cart washing

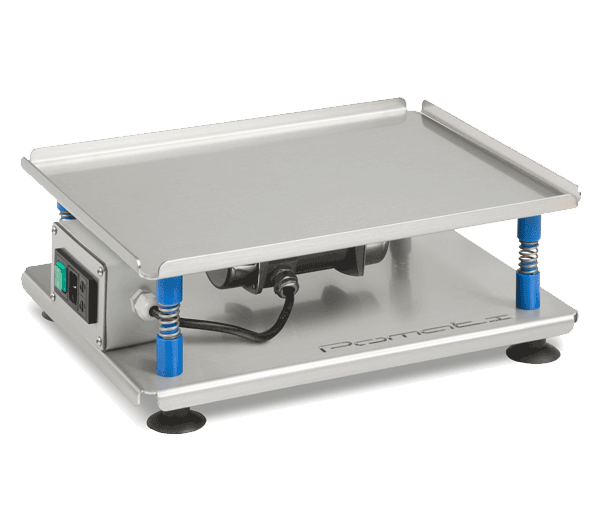

- Aluminum trays for product unloading

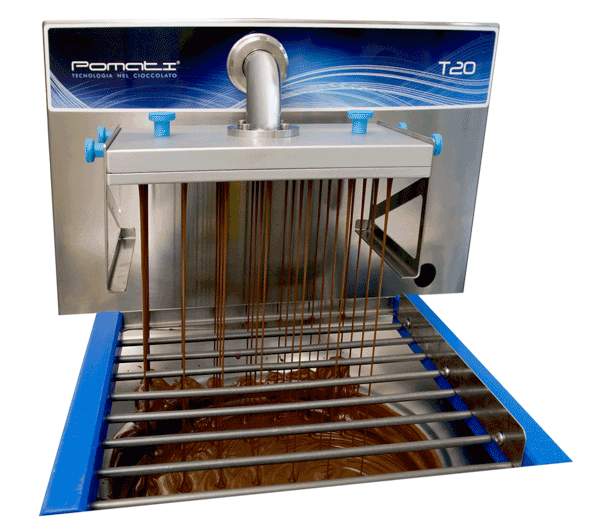

- Double veil hopper for total/partial enrobing

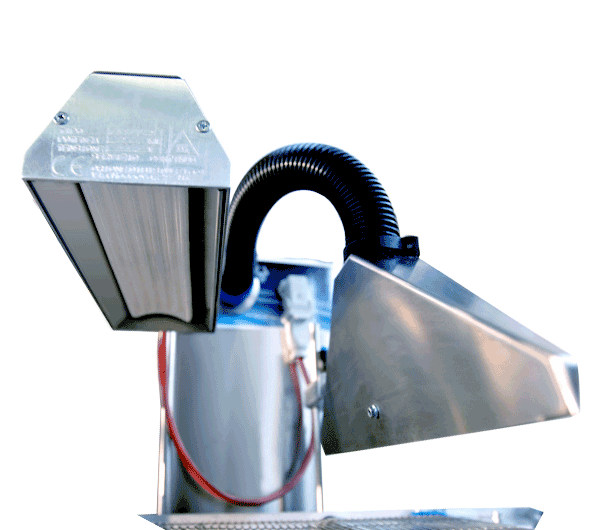

- Variable-speed ventilator with inverter

- Height-adjustable blower featuring a flap top

- Motorized tail cutter with reverse direction

- Tank for lateral and lower enrobing with sinker

- Product height clearance — 160 mm

- Variable 0-2 mt/min speed

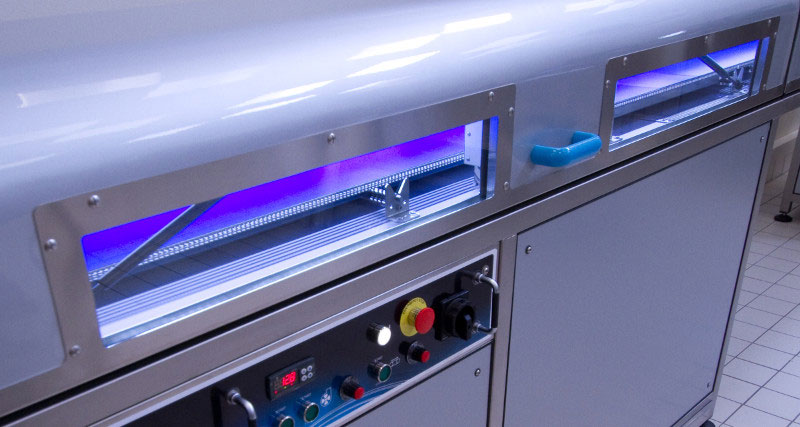

- Heating lamp (optional)

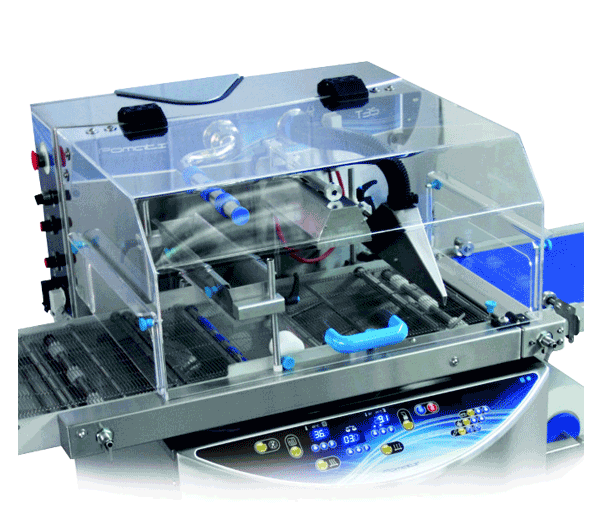

- Plaxiglass Cover (optional)

- Decorator (optional)

Voltage:

230 Volt – Single-phase Hz 50/60 – KW 0,50 (customized voltages upon request)

Available for:

mm 180: T20

mm 250: T20, T35

mm 320: T35

Customized courses for chocolate processing

FOR INFO CONTACT US NOW